Welcome to JANAKS

Design, engineer, deliver : Your Vision, Our expertise

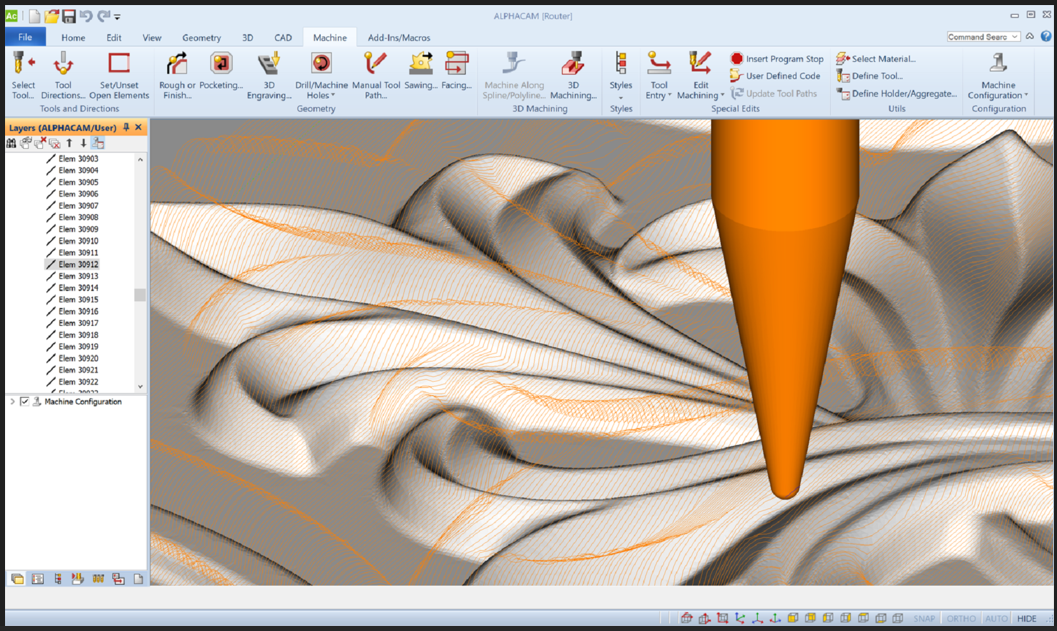

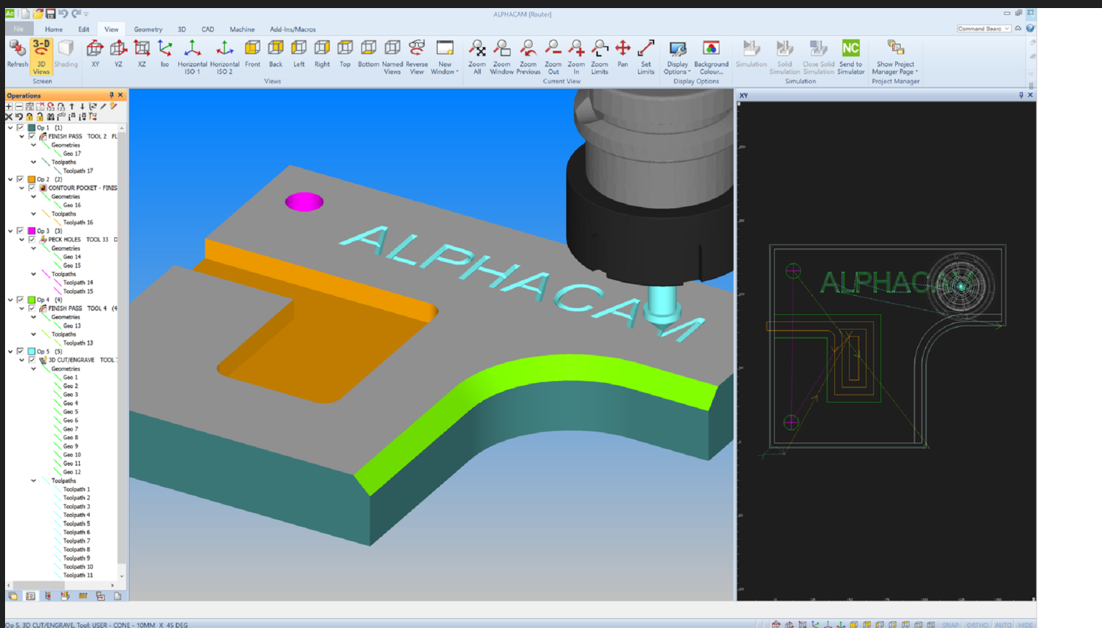

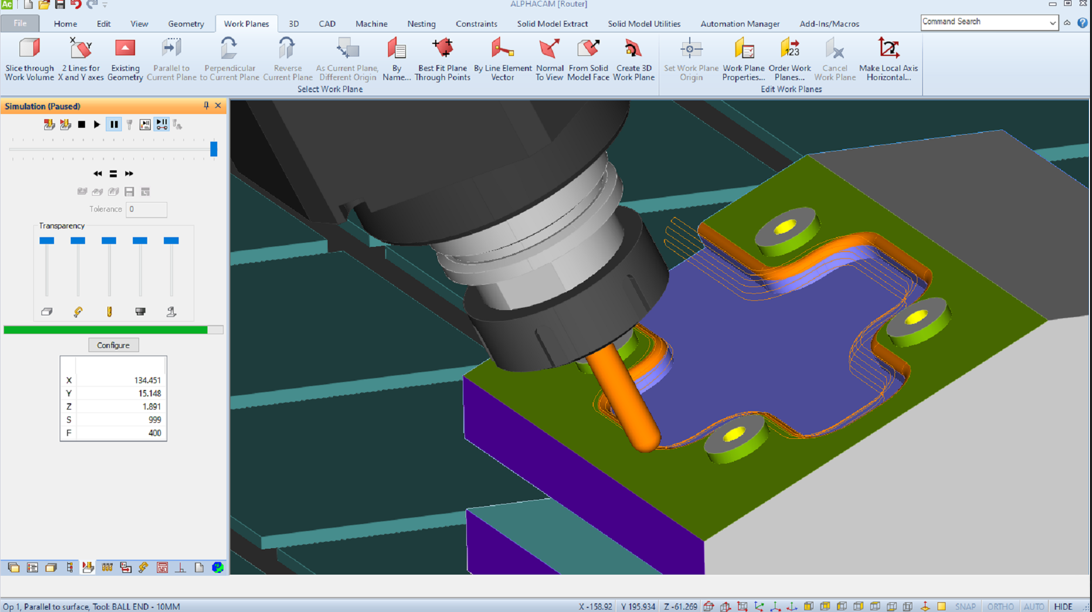

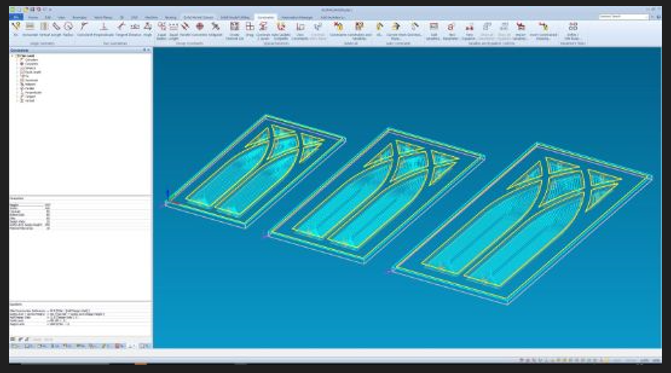

proven machine compatibility ease-of-use is just one of the reasons that alphacam is the industry standard and system of choice for programming cnc routers. tooling and machining techniques unique to this industry are accommodated by alphacam’s dedicated router features.

ALPHACAM Core is the foundation for your manufacturing needs, offering a wide range of essential functionality for part programming. Core includes the ability for CAD importing, toolpath generation, simulation, report generation, and more. Start with ALPHACAM Core for your essential requirements, and add multipliers to build the CAM solution that meets the unique needs of your business.

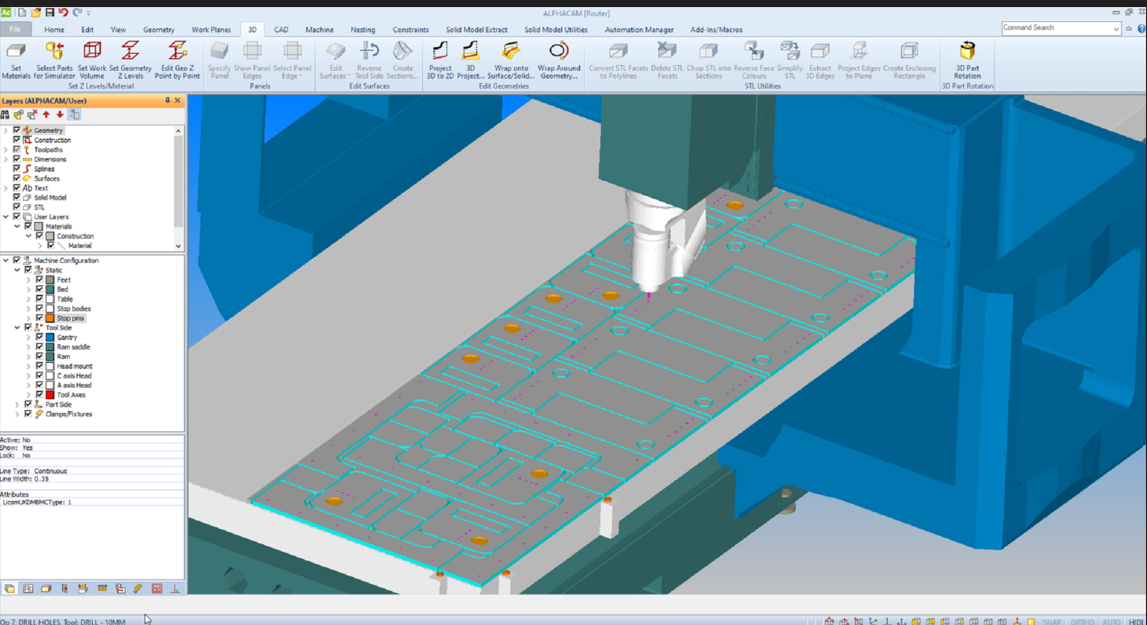

For manufacturers that have 4/5-axis machinery but don’t need the complexity of simultaneous motion toolpaths, the xPositional multiplier is the perfect solutions. By unlocking an additional axis, you will be able to program your machine to cut from any angle.

Support for 5-axis machinery with fully interpolating heads. Head mounted rotary axes on CNC routers can be programmed at any orientation. Aggregates with a programmable rotary axis and manual tilt are fully supported, as well as fully interpolating 5-axis heads. Safe rapid moves between planes are automatically controlled and verified using advanced solid simulation.

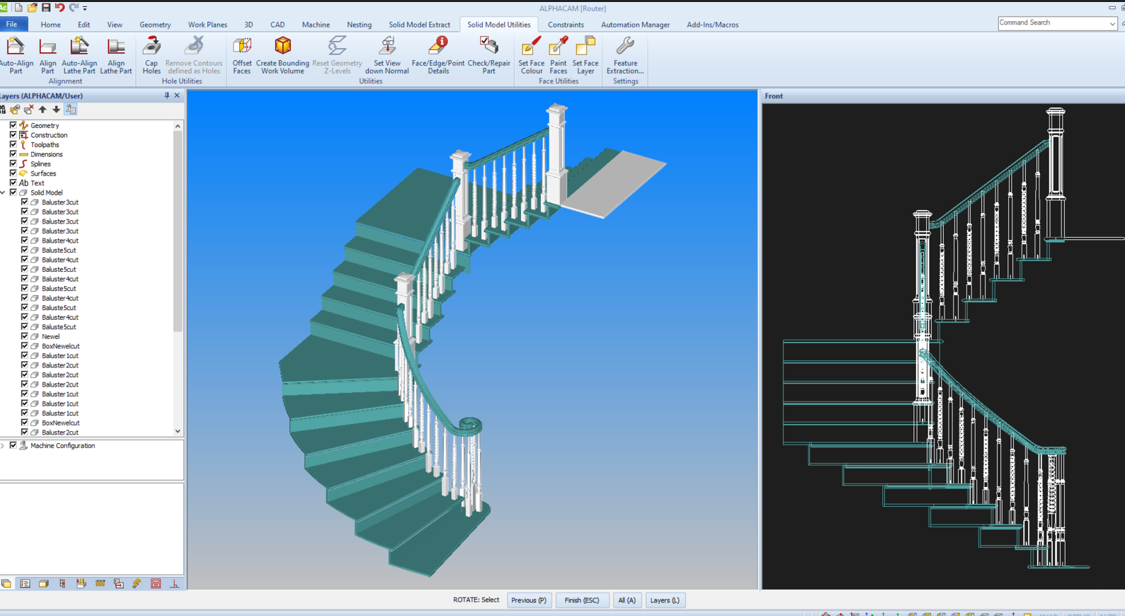

Process your solid models and assemblies and prepare for manufacture If you are working with solid models, xSolids provides the tools you need to import, prepare, and process your files for manufacture. xSolids handles nearly all types of solid models and assemblies, and gives you the ability to automatically recognize features, extract geometries, and apply toolpaths.

Minimize waste by getting the most parts per sheet of material Nested manufacturing is made easy using ALPHACAM’s xNesting multiplier. Parts can be selected directly from the screen or as a kit; their orientation fixed, if grain direction needs to be maintained or rotated to any angle. Nesting supports tool lead in/out, support tags for small parts, avoiding loss of table vacuum and multiple depth cuts, if an onion skin is required.

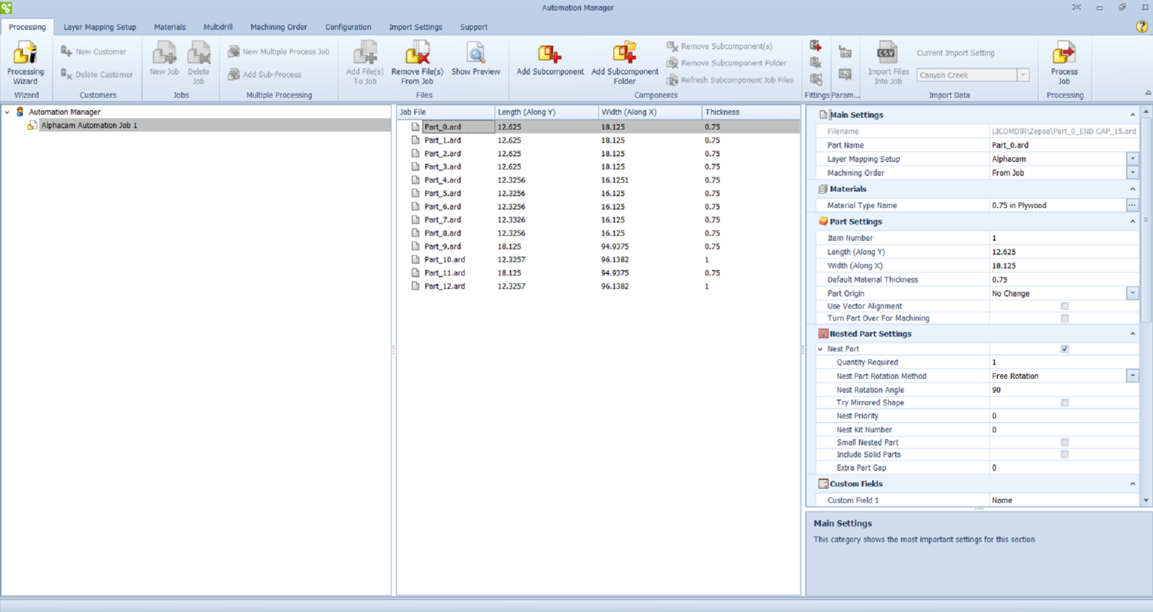

Reduce programming time with smart tools to automate repetitive processes With xAutomation, 2D and 3D CAD files, along with solid models from third party software, can be batch processed - from file preparation right through to applying toolpaths with NC code being generated automatically. In addition, the files create a full report structure, along with labels and bar coding. Using xAutomation can save an end user days and weeks, potentially even months of programming time in a year.

Intelligent handling of smart parts that automatically update based on your rules Parametric part programming can save you hours of time and eliminate errors by creating rules for how certain part attributes are affected when other attributes change. xConstraints gives you the full set of tools and commands to take full advantage of constraints, allowing you to program smart parts with ease.

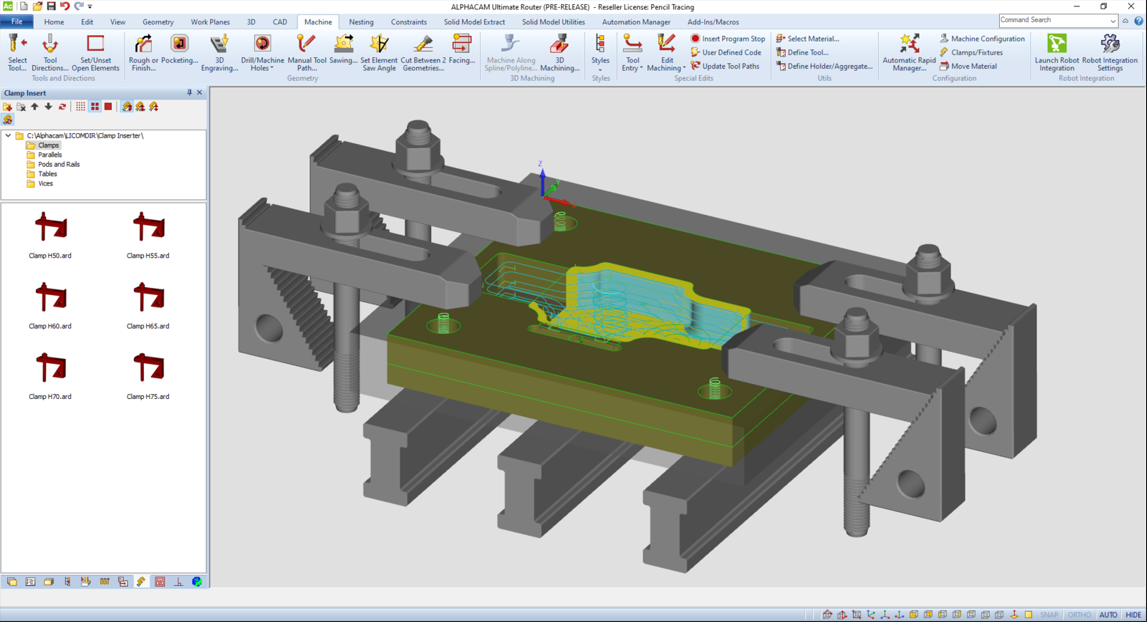

Full control of the design, placement, and simulation of your clamps and fixtures If you need to control the placement, position, and movement of your machinery’s fixtures and clamps within your CAM system, xFixtures is the multiplier for you. Add fixtures to your drawings with drag and drop ease, utilize robust simulation to visualize the placement and motion of your fixtures and materials, or take advantage of features for automatic pod and rail positioning. xFixtures puts you in control.

Extend the power of ALPHACAM to meet your unique needs ALPHACAM’s xAPI multiplier allows you to tap into our powerful CAM engine utilizing standard programming languages to extend and customize the way the software functions. Whether you are looking to create applications that streamline your manufacturing operations, or developing unique programs for custom manufacturing applications, xAPI allows you to take full advantage of the power of ALPHACAM.

If you are needing to output your part programs to be handled by robotics applications, xRobotics is the multiplier for you. We’ve taken the guess work out of what information needs to be output to be best handled by your 3rd party robotics post processor. From tooling, toolpath, and 3D CAD data, xRobotics can help streamline the ability to work with robotic motion cutting tools.

Chennai:

Penthouse, Cordell Apartments, 29, Pycrofts Garden Road, Nungambakkam, Chennai – 600034

Rajapalayam

1085B SVPR Road, Cotton market, Rajapalayam- 626117, Virudhunagar District.

contact@janaks.in

+91 77082 99197

+91 89391 66171